FasTie Quick Ejector Tie-In System quickly “ties-in” the mold ejector plate to the press ejection system in an injection molding press, dramatically reducing mold change time. The greatest time savings are realized in presses where space is limited and the ejector system is difficult to tie in using solid knock-out bars..

In a typical installation, the FasTie coupler is installed into the press ejector plate. The quick-connect locking mechanism in the coupler snaps mechanically onto the mold-mounted stud during mold installation.

To release the ejectors, apply shop air to the coupler. The coupler opens to release the stud, disconnecting the press and tooling ejector plates. The coupler remains in the open position, ready for a new mold to be set.

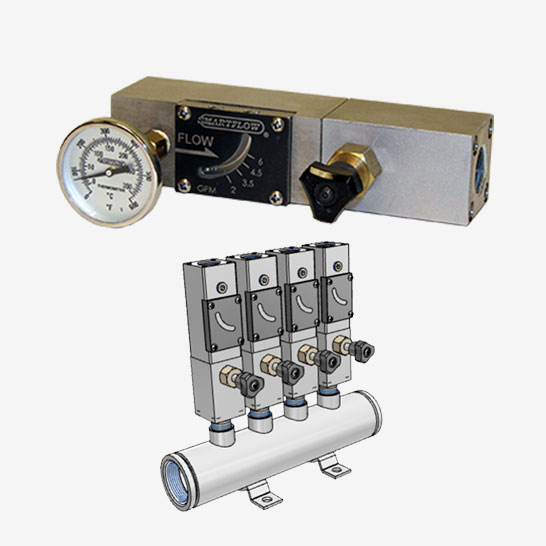

For multiple ejector locations, an air manifold is recommended to release all couplers simultaneously.

Four FasTie sizes are available: 1-inch, 1-3/8 inch, 2-inch, & 3-inch models suitable for most presses and knockout configurations.

Additional installation examples and accessories lists are located in the catalog. Download the .pdf file below.

SPEEDBAR® – Adjustable Knock-Out Bar

(SPEEDBAR® shown with FASTIE® Coupler attached)

SpeedBar is an adjustable length knock-out bar that can quickly compensate for variations in different molds. Used with the FasTie system, mold ejector plate tie-in and adjustment times are reduced to seconds. The adjustment sleeve is easily rotated to change the bar length up to 1-inch in increments of .006″. Once the desired length is set, the spring-loaded sleeve securely locks in your adjustment.

Fixed length knock-out bars are blank on one end for on-site finishing. Longer bars are available.

Fastie Patent No. 6,379,072

SpeedBar Patent No. 6,315,544

Features and Benefits

- Faster Mold Changes

- Various Thread Sizes Available

- Flexible Modular Installation (Center Ejector or Multiple Knockouts)

- No Mold Modifications Required

- Reduced Wear, parts stay connected during molding cycles

- Connects Mechanically

- Disconnects Using Shop Air

- Retracts Completely for Full Ejector Stroke Utilization

- Hardened Steel Materials