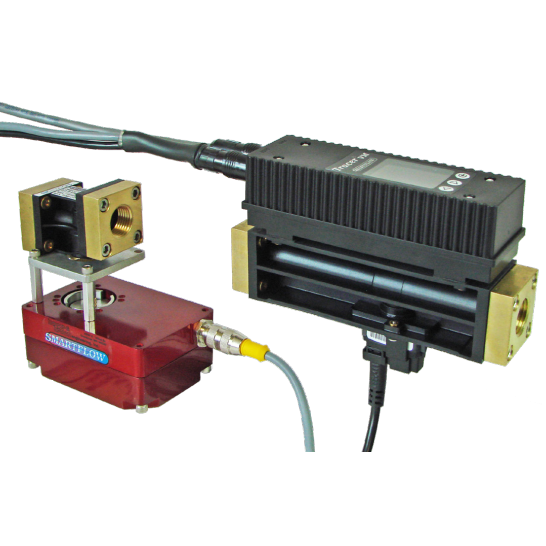

TRACER®vma with AutoReg™

Automatically adjusts flow rate to user-selected value regardless of changes in line pressure. Includes Programmable SPDT Switch, Analog Output and FCI Technology

Tracer®vma Electronic Flowmeter with AutoReg™ automatically adjusts the connected flow regulator opening, resulting in a more consistent flow rate and greater control over cooling water conditions without manual adjustments.Automatic flow regulation compensates for changes in pressure that can occur during normal production due to in-line press startup or shutdown. The AutoReg can be programmed to maintain a steady cooling water flow rate or Reynolds Number essential for consistent molded part quality.

The flowmeter employs reliable vortex shedding sensor technology to monitor liquid flow rate and temperature. The control circuit provides programmable switch set points for high or low flow or temperature and turbulent flow rate (FCI Technology). Analog Outputs for flow and temperature are selectable for connection to data acquisition system or PLC. The totalizing function and BTU’s per minute calculation are also included with this model.

This flowmeter may be ordered with remotely mounted user interface. The user interface can be positioned up to 9.5 feet away from the flow body.

Sealed pushbuttons configure the flowmeter and switch operations through bright color LCD display and user-friendly menus. The SPDT switch can be wired directly to an alarm circuit in a process controller or other peripheral equipment such as low voltage stack lights.

NIST Traceable Calibration is available.

Features and Benefits

- Programmable Target Flow Rate or Reynolds Number

- Separate Analog Outputs (0-3.5/4.1, 0-5 or 0-10V selectable) for temperature and flow

- Actuator Alarm switch notifies the user when minimum flow rate or Reynolds Number cannot be maintained

- Programmable SPDT switch, 1A, 30VAC/30VDC

- Flow rate Display in gallons or liters per minute, +/- 1.5% Accuracy based on full scale

- Temperature Display in degrees Fahrenheit or Celsius, +/- 0.5°C Accuracy

- Volume Totalizer function

- Turbulent Flow Display (FCI)

- Reynolds Number Display

- BTU’s per Minute Calculation with Optional Glycol % Input

- 3/8″, 1/2″, 3/4″ and 1″ NPT(F) or BSPP(F) flow connection sizes

- Local or remote mount user interface

- Accurate Vortex Shedding Sensor Technology

- Pressure gauges are available

Specifications

| Connection Size | Flow Range LPM | Flow Range GPM |

|---|---|---|

| 3/8″ & 1/2″ | 1 to 15 | .3 to 4 |

| 3/8″ & 1/2″ | 2 to 40 | .5 to 10.6 |

| 3/4″ & 1″ | 5 to 100 | 1.3 to 26.4 |

| 1″ | 10 to 200 | 2.6 to 52.8 |

Wetted Parts:

- EPDM Seals

- Flowmeter Body:

* 3/8″ & 1/2″ – Glass-Filled Nylon Body with Brass or Nylon End Caps

* 3/4″, 1″ – Anodized Aluminum or Stainless Steel Body Construction

Environmental:

- Operating Pressure: 150 psi max.

- Operating Temperature: 0 to 120°C (32 to 248°F)

- 1.5A, 24VDC Continuous Power Supply required