MOLDMAX® THERMAL MANAGEMENT SOLUTIONS

High Strength, High Conductivity Alloys for the Plastics Mold Industry

All MoldMAX products are high performance alloys specifcally designed for the

plastic processing industry. These alloys offer a unique combination of thermal

conductivity and strength that provides signifcant advantages for the molding

process, including:

• 15 – 50 % shorter cycle time

• Improved plastic part dimensional control

• Better parting line maintenance

• Corrosion and wear resistance

• Excellent machinability

The MoldMAX product line offers a variety of mold alloys that can ft any application requirement:

MoldMAX HH® • MoldMAX LH® • MoldMAX XL®

MoldMAX V® • PROtherm® • MOLDMAX®

COMPARE MOLDMAX & OTHER PLASTIC TOOLING ALLOYS

|

Plastic Tooling Material |

Rockwell Hardness (HRC) |

Thermal Conductivity (BTU/ft hr °F) |

Charpy V-Notch Impact Strength |

Yield Strength (ksi) |

Tensile Strength (ksi) |

Expansion Coefficient (10-6/in/in/°F) |

|

420 Stainless |

50 |

10 |

5-10 |

200 |

250 |

6.1 |

|

H-13 Tool Steel |

45-50 |

15 |

8-14 |

200 |

250 |

7.1 |

|

MoldMAX HH® |

40 |

75 |

4 |

145 |

170 |

9.7 |

|

MoldMAX XL® |

30 |

40 |

15 |

105 |

115 |

9.3 |

|

MoldMAX LH® |

30 |

90 |

12 |

110 |

140 |

9.7 |

|

MoldMAX V® |

28 |

92 |

8 |

105 |

125 |

9.7 |

|

P-20 Tool Steel |

30 |

17 |

25 |

120 |

140 |

7.1 |

|

PROtherm® |

20 |

145 |

40 |

90 |

105 |

9.8 |

|

ThermoMet |

16 |

120 |

35 |

65 |

96 |

9.7 |

|

Alumold® * |

B88 |

95 |

30 |

75 |

80 |

12.9 |

|

QC-10® ** |

92.2 |

66-76 |

13.7 |

Materion alloys are in bold.

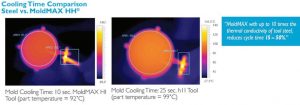

THERMAL CONDUCTIVITY ADVANTAGE

Mold designs that optimize the superior combination of thermal conductivity and strength of MoldMAX alloys will provide rapid, uniform and controlled heat removal from the plastic part. The immediate beneft is less in-mold and post-mold warpage of plastic parts, as well as shorter cycle time and better dimensional control. In addition, hot runner and manifold designs that include MoldMAX alloys will result in more uniform temperature control of the plastic melt and higher quality plastic parts.

THE MOLDMAX® ADVANTAGE IN INJECTION MOLDING

MoldMAX is engineered for use as the core material in concert with steel mold bases and cavities. One of the most important functions of an injection mold is to act as a heat exchange. The core performs the majority of the heat removal in the typical mold.MoldMAX with up to 10 times the thermal conductivity of tool steel, reduces cycle time 15 – 50%. The cost savings of these reductions can be substantial.